You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

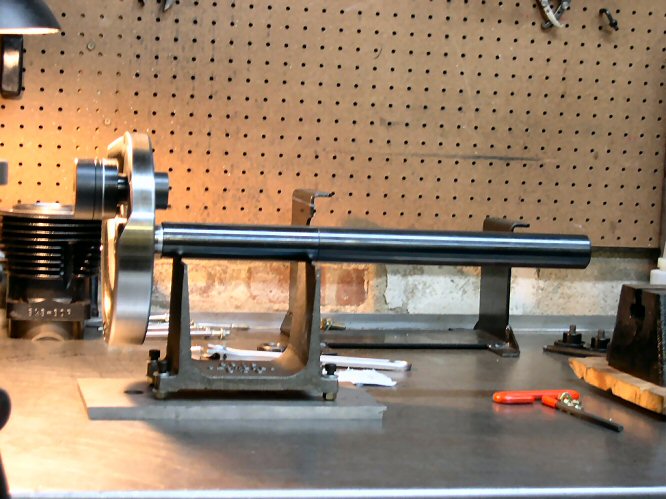

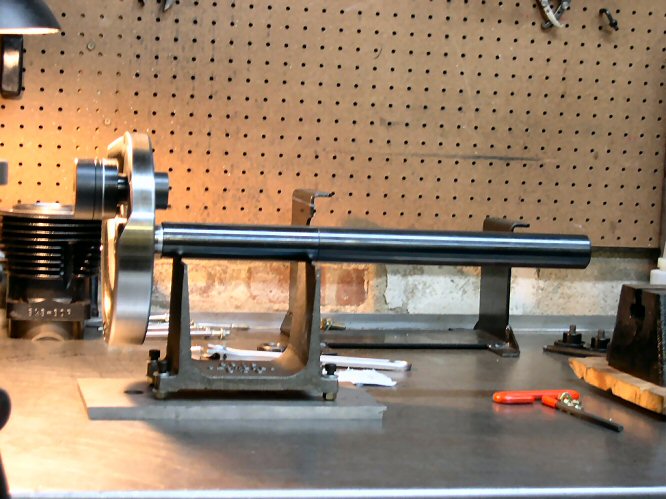

Balancing an 80mm 650 crank

- Thread starter bushmechanic

- Start date

Help Support Husaberg:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Sep 30, 2007

- Messages

- 782

- Location

- ???

Great stuff Bushie :cheers:

I checked the weight of the stock 628 crank on a set of accurate digital scales comes in at 4.58Kg

second one was 4.59kg.

What is yours weighing now?

Did the balancing act and the bob weight came in exactly the same as yours at 148grms :cheers:

Got the prox big end pins here now the ktm 450 pin weight is 391 grms but would be about 15mm lighter (around 376grms) once trimmed to the same length the Husabergs pin weighs 348grms.

But would be about 15mm lighter (around 376grms) once trimmed to the same length

the prox pin and bearing is tighter fit than the Husagerg components, maybe to tight. Have not checked

yet to see if the pin is bigger or the rollers.

The prox 450 pin has the oil inlet hole rotated by 135 degrees in relation to the outlet hole so maybe a hole would need to drilled.

The prox cage is 3grms less than the Husabergs.

Cheers spanner

I checked the weight of the stock 628 crank on a set of accurate digital scales comes in at 4.58Kg

second one was 4.59kg.

What is yours weighing now?

Did the balancing act and the bob weight came in exactly the same as yours at 148grms :cheers:

Got the prox big end pins here now the ktm 450 pin weight is 391 grms but would be about 15mm lighter (around 376grms) once trimmed to the same length the Husabergs pin weighs 348grms.

But would be about 15mm lighter (around 376grms) once trimmed to the same length

the prox pin and bearing is tighter fit than the Husagerg components, maybe to tight. Have not checked

yet to see if the pin is bigger or the rollers.

The prox 450 pin has the oil inlet hole rotated by 135 degrees in relation to the outlet hole so maybe a hole would need to drilled.

The prox cage is 3grms less than the Husabergs.

Cheers spanner

- Joined

- Jun 13, 2007

- Messages

- 3,861

- Location

- south east WA Australia

Interesting stuff Spanner

I used the prox KTM pin with my old original rod in the 700 it worked well, noticed the press fit was tighter and the big end was not too tight.. but it is an old rod had 220hrs on it at that stage, I used the OEM big end bearing

I probably mic-ed the pin .. will have a look

on my fish scales crank rod etc now weighs about 4.1kgs assembled

i have the weights of the individual parts recorded at work will post them up

Kaffey I may have some pics somewhere of removal on the 550 crank.

I used the prox KTM pin with my old original rod in the 700 it worked well, noticed the press fit was tighter and the big end was not too tight.. but it is an old rod had 220hrs on it at that stage, I used the OEM big end bearing

I probably mic-ed the pin .. will have a look

on my fish scales crank rod etc now weighs about 4.1kgs assembled

i have the weights of the individual parts recorded at work will post them up

Kaffey I may have some pics somewhere of removal on the 550 crank.

- Joined

- Sep 30, 2007

- Messages

- 782

- Location

- ???

Bushie,

That is handy to know that the ktm pin is a bit tighter, would help with flywheel locking.

How did you get on with the oil hole being out of alignment by 135 degrees or did you just line it up and

have the outlet out 135 degrees ? Might not help longevity to have the outlet in a high load area.

Other than the way they are drilled for oiling, why could the big end pins not be tapered at there

ends like wrist pins. Oil could be easily be drill differently.

Cheers spanner

That is handy to know that the ktm pin is a bit tighter, would help with flywheel locking.

How did you get on with the oil hole being out of alignment by 135 degrees or did you just line it up and

have the outlet out 135 degrees ? Might not help longevity to have the outlet in a high load area.

Other than the way they are drilled for oiling, why could the big end pins not be tapered at there

ends like wrist pins. Oil could be easily be drill differently.

Cheers spanner

- Joined

- Jun 13, 2007

- Messages

- 3,861

- Location

- south east WA Australia

i figured the oil hole location didn't really matter because the main wear in mine comes from the cage which is trying to get out at all directions

maybe tapering a pin may reduce the degree of crush at the outer surface of the flywheels... or maybe not

if it did then welding would fix the issue

maybe tapering a pin may reduce the degree of crush at the outer surface of the flywheels... or maybe not

if it did then welding would fix the issue

- Joined

- Sep 30, 2007

- Messages

- 782

- Location

- ???

Some nice steel here for a crank pin, would Only be suitable for plain bearing use as it can only be hardened to 53-55HRC.

Might get some 8)

http://www.ebay.com.au/itm/300368627823 ... 1423.l2649

Might get some 8)

http://www.ebay.com.au/itm/300368627823 ... 1423.l2649

- Joined

- Jun 13, 2007

- Messages

- 3,861

- Location

- south east WA Australia

nice

is that $ 107 au per pund for shipping?

shipito again

is that $ 107 au per pund for shipping?

shipito again

Bushie, have you considered balancing each crank wheel independently?

some decent balancing refrences Ive found:

http://www.tonyfoale.com/AermacchiEngin ... alance.pdf

http://www.tonyfoale.com/Articles/Engin ... alance.pdf

http://www.caimag.com/wordpress/2011/05 ... w-i-do-it/

and a balance factor calculator:

http://www.tonyfoale.com/software.htm

some decent balancing refrences Ive found:

http://www.tonyfoale.com/AermacchiEngin ... alance.pdf

http://www.tonyfoale.com/Articles/Engin ... alance.pdf

http://www.caimag.com/wordpress/2011/05 ... w-i-do-it/

and a balance factor calculator:

http://www.tonyfoale.com/software.htm

- Joined

- Jun 13, 2007

- Messages

- 3,861

- Location

- south east WA Australia

Hi Jar

those articles and pics are very good, thanks for posting them up :cheers:

I really like this pin design

that's a great idea balancing them separately, also looks like they are trying very hard to replicate things

I have no idea if this will be good or not so i didn't want to spend too much time on it

I forgot to shot peen the rod so I'll do it with the needle scaler

cheers

Bushie

those articles and pics are very good, thanks for posting them up :cheers:

I really like this pin design

that's a great idea balancing them separately, also looks like they are trying very hard to replicate things

I have no idea if this will be good or not so i didn't want to spend too much time on it

I forgot to shot peen the rod so I'll do it with the needle scaler

cheers

Bushie

- Joined

- Jun 13, 2007

- Messages

- 3,861

- Location

- south east WA Australia

FArk yeah!

very nice Spanner :cheers: :cheers: :cheers: :cheers: :cheers:

I see you made some room for the bigger rod as well ?

very nice Spanner :cheers: :cheers: :cheers: :cheers: :cheers:

I see you made some room for the bigger rod as well ?

- Joined

- Jun 13, 2007

- Messages

- 3,861

- Location

- south east WA Australia

based on other balancers I have seen I think that any adjustment toward a generally accepted value would involve making it heavier

there is supposedly a secret formula to match the reciprocating parts to the CB but i don't know anything about it.

from what ive found, the CB also only really does any smoothing at low rpm, at high rpm it adds a buzzy feel to the problem. the balancing of the CB is supposed to reduce the buzzy feel at high rpm

maybe if you grind it right down it will feel as good as my bike :twisted:

there is supposedly a secret formula to match the reciprocating parts to the CB but i don't know anything about it.

from what ive found, the CB also only really does any smoothing at low rpm, at high rpm it adds a buzzy feel to the problem. the balancing of the CB is supposed to reduce the buzzy feel at high rpm

maybe if you grind it right down it will feel as good as my bike :twisted:

- Joined

- Sep 30, 2007

- Messages

- 782

- Location

- ???

Well I have perhaps found the true weak point in the Husaberg 628 crankshaft hidden under the shot peening.

No need for incomplete fancy finite analysis either. :roll:

Just a bit of grinding and rubbing with a bit of rock and watch the cracks appear.

Crack on right is highlighted with red ball point pen.

Other cracks do not need highlighting.

This one headed for the welders to have extra added, or the bin :cry:

No need for incomplete fancy finite analysis either. :roll:

Just a bit of grinding and rubbing with a bit of rock and watch the cracks appear.

Crack on right is highlighted with red ball point pen.

Other cracks do not need highlighting.

This one headed for the welders to have extra added, or the bin :cry:

- Joined

- Jun 13, 2007

- Messages

- 3,861

- Location

- south east WA Australia

interesting spanner

I suppose they are possibly all like that though ?

I suppose they are possibly all like that though ?

- Joined

- Sep 30, 2007

- Messages

- 782

- Location

- ???

Quite possibly Bushie,

I am starting to think the cracks in the centre are some sort of inclusion

from the manufacturing process.

Not sure what they were thinking thinning it down right opposite the main bearing pin.

The crack highlighted with the ball point looks to me to be perhaps from torsional load,

being on the drive side. May be.

I have another flywheel so I will dress the same area and see if it the same.

Not sure about welding, but seems to be quite commonly done when they make stroker

cranks etc, would be nice to know the material it is made from?

Could fill in quite a bit of that area.

Cheers spanner

I am starting to think the cracks in the centre are some sort of inclusion

from the manufacturing process.

Not sure what they were thinking thinning it down right opposite the main bearing pin.

The crack highlighted with the ball point looks to me to be perhaps from torsional load,

being on the drive side. May be.

I have another flywheel so I will dress the same area and see if it the same.

Not sure about welding, but seems to be quite commonly done when they make stroker

cranks etc, would be nice to know the material it is made from?

Could fill in quite a bit of that area.

Cheers spanner

- Joined

- Jun 13, 2007

- Messages

- 3,861

- Location

- south east WA Australia

I think they use stellite 6 TIG filler rod on the ktms

I know its the same as they use for building up camshafts

I know its the same as they use for building up camshafts

- Joined

- Sep 30, 2007

- Messages

- 782

- Location

- ???

Solved the crack mystery I think:unsure:

Seen similar cracks in tooling where a thinner section is

surrounded by a larger section, when quenched the thin

section contracts first more than the still hotter larger section

creating enough stress to crack the thinner section.

Being Case hardened it may only be a surface crack around

the depth of the case

Both flywheels are cracked the same, a third one has no crack

so may have been quenched different or from a lower temperature.

Going to use them.

Have shaved 250g total off so far, next step is to re-balance

to the STD factor by surface grinding material of the inside

flat faces as marked.

Might get a total reduction of around 500g from the crank

Thinking counter balancer will not need adjustment?:unsure:

I have an idea I can save around 30g from the STD big end pin still

thinking that one out

Cheers spanner

Seen similar cracks in tooling where a thinner section is

surrounded by a larger section, when quenched the thin

section contracts first more than the still hotter larger section

creating enough stress to crack the thinner section.

Being Case hardened it may only be a surface crack around

the depth of the case

Both flywheels are cracked the same, a third one has no crack

so may have been quenched different or from a lower temperature.

Going to use them.

Have shaved 250g total off so far, next step is to re-balance

to the STD factor by surface grinding material of the inside

flat faces as marked.

Might get a total reduction of around 500g from the crank

Thinking counter balancer will not need adjustment?:unsure:

I have an idea I can save around 30g from the STD big end pin still

thinking that one out

Cheers spanner

Similar threads

- Replies

- 32

- Views

- 13K

Register CTA

Register on Husaberg Forum! This sidebar will go away, and you will see fewer ads.

Sign Up