Joined May 2005

190 Posts | 145+

Sacramento California

I've been working on this project for some time now and am finally at the point where I feel it's time to start a thread to document the build.

My history with Husabergs dates back to...well...before there were Husabergs. I was a Husqvarna guy in the 80's. My first was an '83 CR 250. Then I had an '83 CR 500, but the standout Husky for me was the '87 TC510 that I bought used in 1988. I was hooked right away.

In 1996 my brother bought a 1995 Husaberg FE501. I was amazed at how much better that bike was than the old 510. The hook sank in even deeper.

I've accumulated a few other Husabergs over the years culminating in a 2008 FE550 I bought for the specific purpose of racing the 2011 Vegas to Reno desert race. The bike was so exceptional everywhere that we ended up getting 8th overall. Sadly, I was forced to sell that bike to fund the refurbishment of the bathroom in my old house.

Ever since then I've intended to build the ultimate Husaberg for myself. I wanted to start with something cheap because I was going to basically rebuild everything on the bike so, no sense breaking the bank right off the bat.

I found a 1996 FC600 that I ended up purchasing for $400. I've posted about this bike plenty in other threads but, to recap, it had fallen out of the previous owner's truck and tumbled down the highway so it was thoroughly beat.

Here's after spending a ton of time getting it at least worthy of a photo.

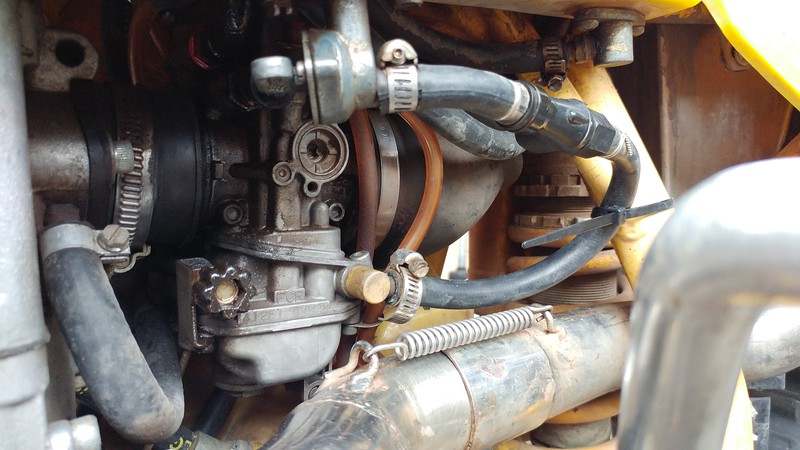

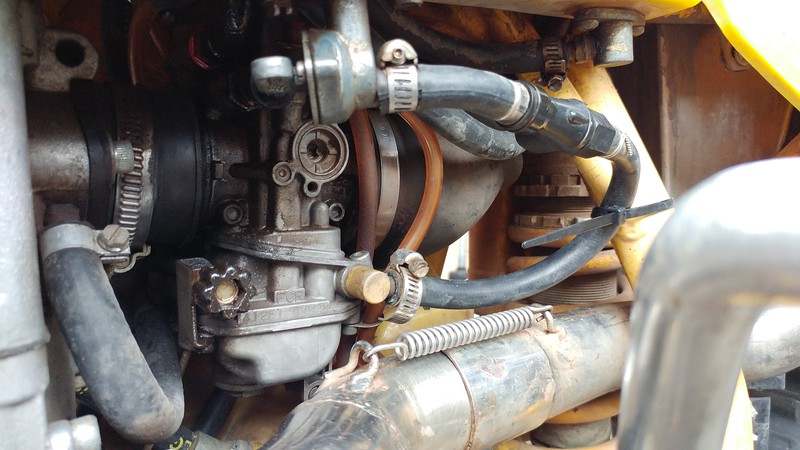

Added a Keihin FCR41MX from a 2008 KTM 450SXF.

Swapped to 2013 KTM closed chamber forks and front brake with an Excel A60 laced to a KTM hub.

Added an Eric's Machine aux tank I found on Ebay for a song and rigged up a pair of mounts for the stock fender flap.

Plumbed it to the stock tank via a quick disconnect and an inline valve.

Then I installed Taffy's graphics and seat cover and here's where she's at today.

In addition to the cosmetic damage it had when I saved her, the engine was locked up. Since I was in the process of building my http://husaberg.org/mechanical/16703-husaberg-ktm-hybrid-engine.html I decided that here was my recipient for the engine.

I have a second FC600 engine that I bought off of a guy in Boise who planned to install it in a go-kart but lost enthusiasm for the project (presumably when he discovered how difficult it would be to start with no electric boot). I always intended to do something crazy with this engine so...Here it comes!

My history with Husabergs dates back to...well...before there were Husabergs. I was a Husqvarna guy in the 80's. My first was an '83 CR 250. Then I had an '83 CR 500, but the standout Husky for me was the '87 TC510 that I bought used in 1988. I was hooked right away.

In 1996 my brother bought a 1995 Husaberg FE501. I was amazed at how much better that bike was than the old 510. The hook sank in even deeper.

I've accumulated a few other Husabergs over the years culminating in a 2008 FE550 I bought for the specific purpose of racing the 2011 Vegas to Reno desert race. The bike was so exceptional everywhere that we ended up getting 8th overall. Sadly, I was forced to sell that bike to fund the refurbishment of the bathroom in my old house.

Ever since then I've intended to build the ultimate Husaberg for myself. I wanted to start with something cheap because I was going to basically rebuild everything on the bike so, no sense breaking the bank right off the bat.

I found a 1996 FC600 that I ended up purchasing for $400. I've posted about this bike plenty in other threads but, to recap, it had fallen out of the previous owner's truck and tumbled down the highway so it was thoroughly beat.

Here's after spending a ton of time getting it at least worthy of a photo.

Added a Keihin FCR41MX from a 2008 KTM 450SXF.

Swapped to 2013 KTM closed chamber forks and front brake with an Excel A60 laced to a KTM hub.

Added an Eric's Machine aux tank I found on Ebay for a song and rigged up a pair of mounts for the stock fender flap.

Plumbed it to the stock tank via a quick disconnect and an inline valve.

Then I installed Taffy's graphics and seat cover and here's where she's at today.

In addition to the cosmetic damage it had when I saved her, the engine was locked up. Since I was in the process of building my http://husaberg.org/mechanical/16703-husaberg-ktm-hybrid-engine.html I decided that here was my recipient for the engine.

I have a second FC600 engine that I bought off of a guy in Boise who planned to install it in a go-kart but lost enthusiasm for the project (presumably when he discovered how difficult it would be to start with no electric boot). I always intended to do something crazy with this engine so...Here it comes!